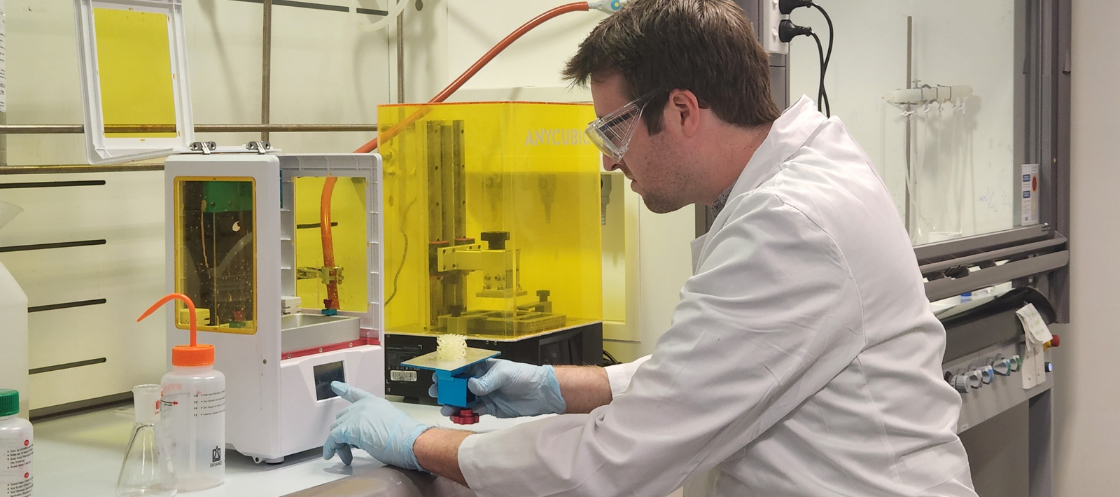

New 3D printing process offers novel energy storage design options

UNSW engineers have developed a process to print solid-state polymer electrolytes into any shape desired for use in energy storage.

The research team from the School of Chemical Engineering – led by Professor Cyrille Boyer, and including Dr Nathaniel Corrigan and Kenny Lee – say the 3D printing process of such material could be particularly useful in future medical devices where small, intricately designed energy storage offers a number of benefits.

Solid-state electrolytes are a key component in solid-state batteries, although traditionally they have suffered from poor performance due to low ionic conductivities or poor mechanical properties.

However, in a paper published in Advanced Materials, the team from UNSW reports their 3D printed solid polymer electrolyte (SPE) offers high conductivity, as well as robust strength.

This means the solid-state electrolytes can potentially be used as the actual structure of a device, creating a range of conceivable design opportunities, particularly for future medical products.

“Nobody has 3D printed solid polymer electrolytes before. Traditionally they have been made using a mould, but previous processes did not offer the ability to control the strength of the material, or to form it into complex shapes,” says Kenny Lee.

“With existing solid-state electrolytes when you increase the mechanical strength of the material, you sacrifice a lot of the conductivity. If you want higher conductivity the material is much less robust. What we have achieved is a simultaneous combination of both, which can be 3D printed into sophisticated geometries.

“This polymer electrolyte has the potential to be a load-bearing energy storage material. Because of its strength, it could be used as the actual structure of small electronics, or in aerospace applications, or in small personal medical devices given our 3D printing process can be very intricate and precise.

Although the solid polymer electrolyte developed by the UNSW team is regarded as a high-performance material, the researchers say it can be manufactured using inexpensive and commercially available 3D printers, rather than sophisticated engineering equipment.